“Spring wash” is what happens when colorant product washes away due to high moisture levels, typically during the spring season. Even the highest-quality mulch colorant can experience washing if the colorant isn’t fully dried.

“Spring wash” is what happens when colorant product washes away due to high moisture levels, typically during the spring season. Even the highest-quality mulch colorant can experience washing if the colorant isn’t fully dried.

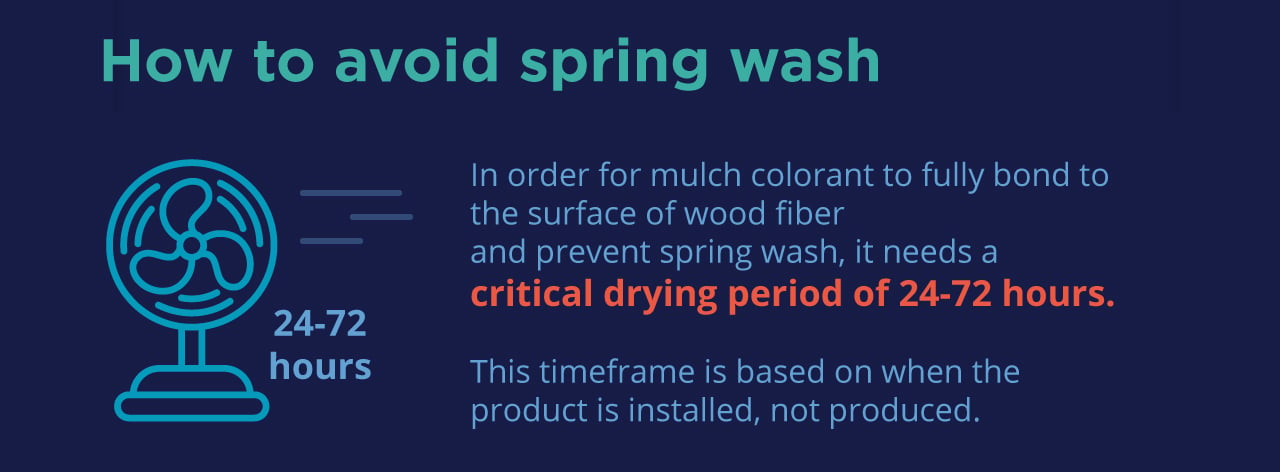

How to avoid spring wash

In order for mulch colorant to fully bond to the surface of wood fiber and prevent spring wash, it needs a critical drying period of 24-72 hours. This time frame is based on when the product is installed, not produced. Adhering to this time period will give you optimal results for your finished product.

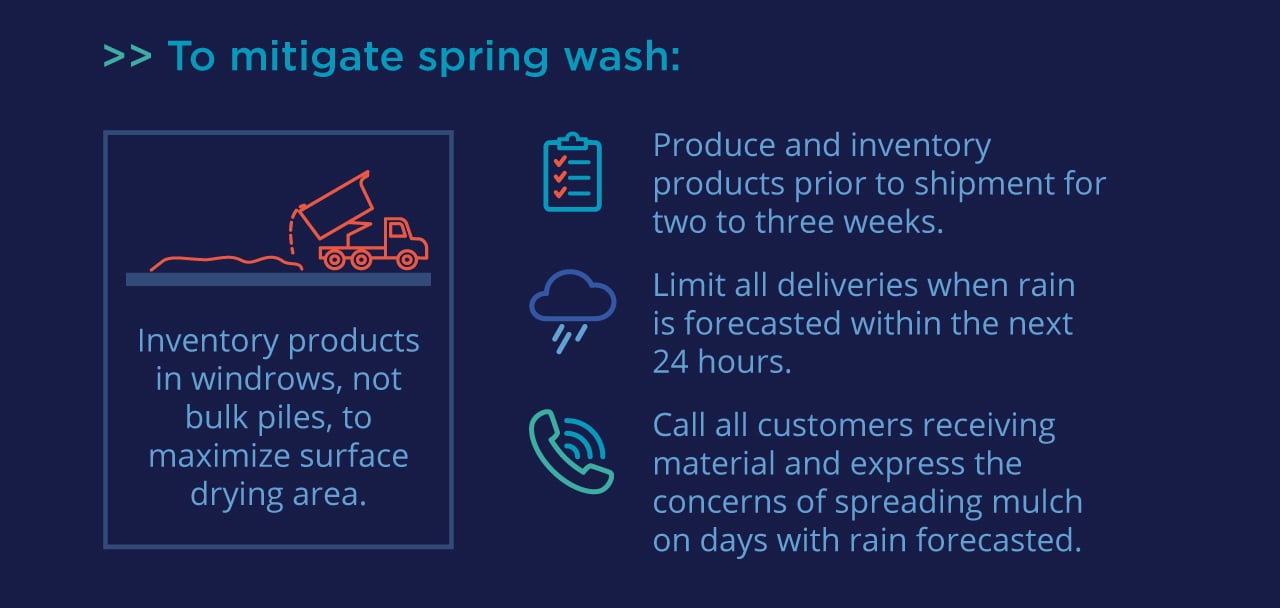

To mitigate spring wash:

- Inventory products in windrows, not bulk piles, to maximize surface drying area.

- Produce and inventory products prior to shipment for two to three weeks.

- Limit all deliveries when rain is forecasted within the next 24 hours.

Call all customers receiving material and express the concerns of spreading mulch on days when rain is in the weather forecast. Customers want a product that last, so most will be willing to wait.

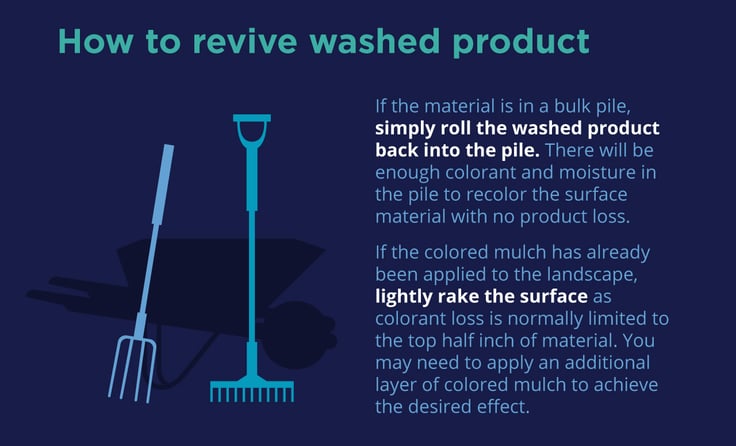

How to revive washed product

If the material is in a bulk pile, simply roll the washed product back into the pile. There will be enough colorant and moisture in the pile to recolor the surface material with no product loss.

If mulch colorant has already been applied to the landscape, lightly rake the surface as colorant loss is normally limited to the top half inch of material. You may need to apply an additional layer of mulch to achieve the desired effect.

Like what you see? Download the Spring Wash Infographic so you'll have it for quick reference!