What is the first thing you think when your finished product looks different than it usually does? It must be my colorant; I need to call my vendor.

What is the first thing you think when your finished product looks different than it usually does? It must be my colorant; I need to call my vendor.

Think of it this way. Your Grandmother always made the best biscuits and showed you how to make those fluffy, flaky, buttery bites of goodness. A measured amount of flour, baking powder, cream and butter, kneaded for a certain amount of time, rolled out and cut just right and baked at the correct temperature. Then one day your biscuits just don’t taste the same. Would you think Grandma’s recipe was suddenly wrong and needed to be changed? Did the flour, butter or cream change? Did the oven stop keeping the same temperature? Most likely something changed in the biscuit-making process.

If your colored mulch doesn’t look up to your standards there are a few things you should check. Take these steps to identify why the color of your finished product mulch may look different.

1. Colorant Application Rates

Calibrate the colorant pump to verify your standard colorant application rates are still in place. The hose in the colorant pump could be worn out and not delivering the correct amount of colorant. Has your production rate changed? The production rate directly affects the per-yard, colorant application rate.

2. Water Use Rates

Water is the driver of coverage. It carries the colorant over the wood chip surface area to produce an evenly coated, finished product. If too much water is used your finished product's drying or curing time can be extended and could lead to "spring wash." If too little water is used you could see uncovered or uncolored wood particles. Be sure to check if the correct amount of water being used.

3. Raw Material

Did your raw material change in type, shade or particle size? Finished product shade is directly related to raw material shade. If the raw material has a higher percentage of fines (¼” minus pieces) this could affect water-use rates and the amount of colorant needed to achieve the same finished product appearance.

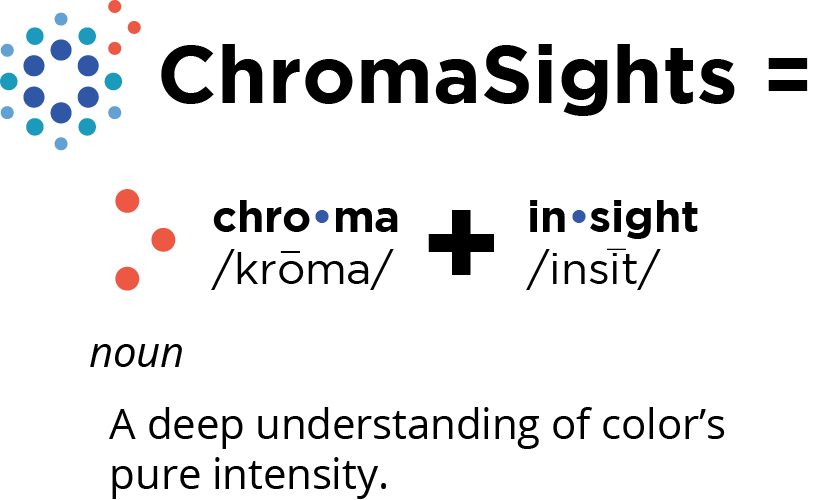

In most cases one of these three things is the culprit for the change in your final product. Contact ChromaScape and speak with your Amerimulch sales manager who can help you investigate the reason for this change.